Extraordinary Quality Is Our Best Sales

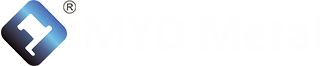

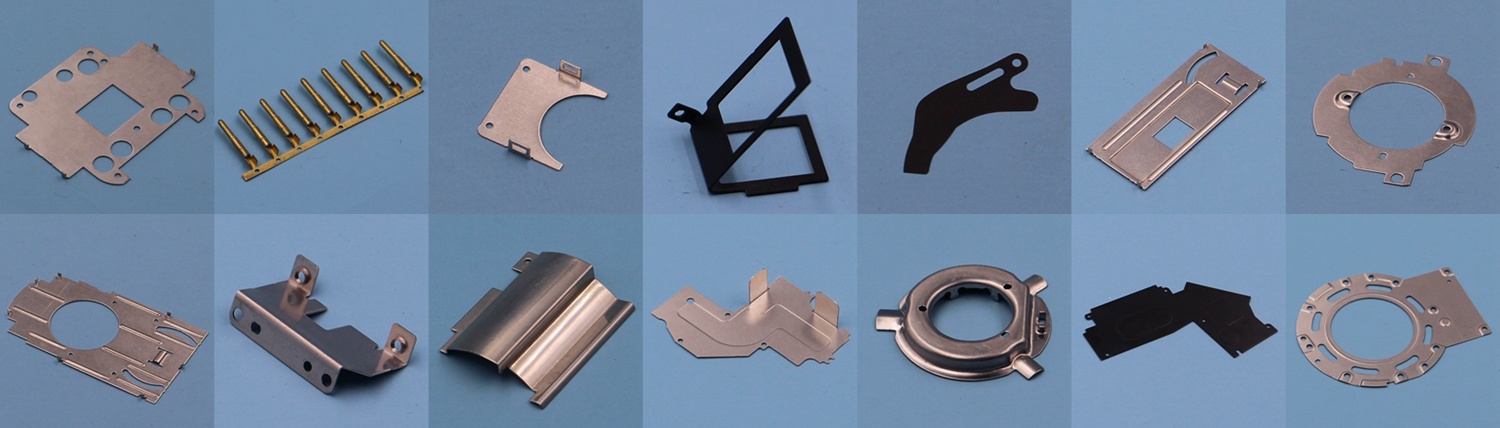

● Brackets, chassis plates, mounting fixture parts

In the products of various industries, it is often necessary to use some brackets, bottom plates, and mounting fixtures. We can choose the appropriate materials and surface treatment methods according to the needs of the products, while solving the product needs perfectly, and saving costs as much as possible.

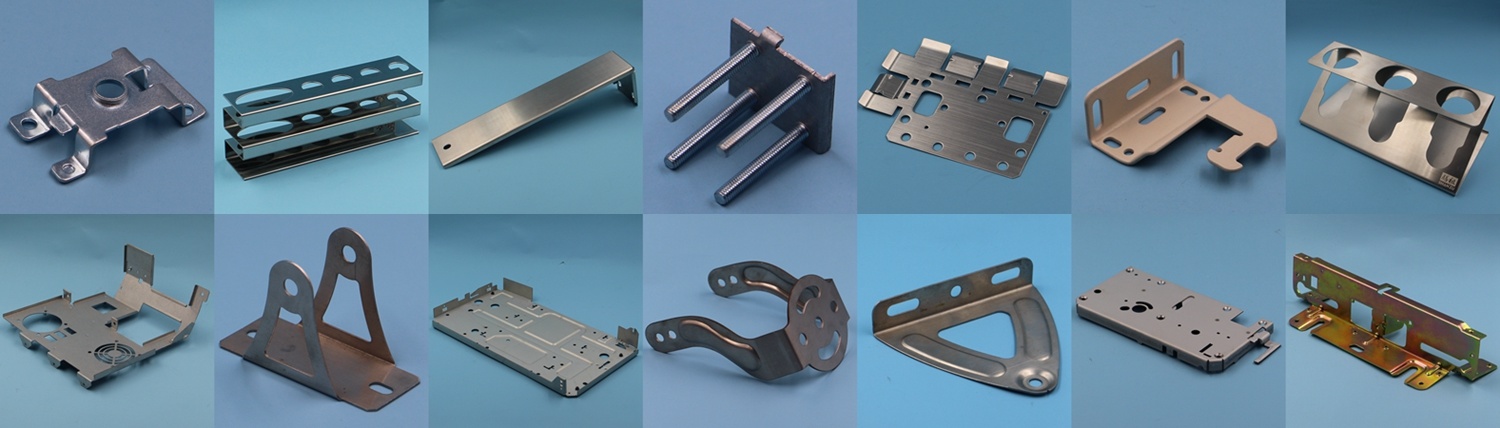

● Sheet metal manufacturing products

Our company is equipped with laser cutting, CNC bending and welding grinding departments, which are very convenient for sheet metal fabrication. Sheet metal products are mainly made from three types of materials: cold rolled steel, stainless steel, and aluminum alloy, and the surface treatment methods can be powder coating, brushing, polishing, bead blasting, anodizing, etc.

● Battery contacts, electrical contacts, terminals

We are good at making all kinds of battery contacts, electrical contacts, terminals and other parts. The pictures show some examples we have customized for customers. They are mainly made of copper alloys such as phosphor bronze, brass and beryllium copper, but sometimes materials such as stainless steel and spring steel are used. The surface treatment methods include nickel plating, tin plating and silver plating.

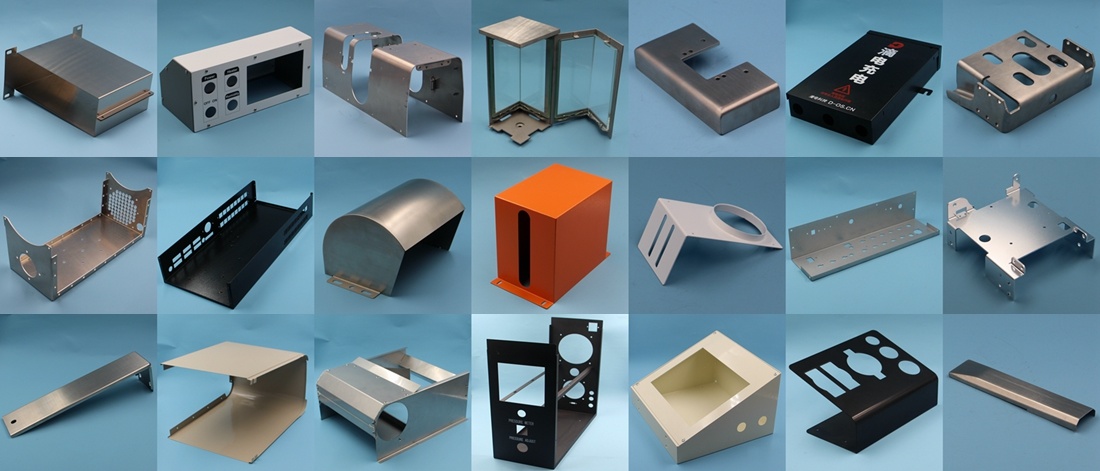

● Metal clips, flat spring parts

Metal clips and flat spring are one of the most common types of parts we make. They are usually made of stainless steel and spring steel, but we can also produce these products from aluminum, brass, beryllium copper, high carbon steel and low carbon steel.in some cased, the use of annealed material is vital in order for the high carbon steel to undergo complex forming. The material is then heat-treated and tempered to obtain its full spring characteristics.

● Optical and electronic high precision metal parts

These are some of our high-precision stamping parts, some of them are zoom lens accessories, some are instrument accessories, and some are electronic equipment accessories, mainly made of stainless steel or copper alloy or aluminum alloy. We can achieve dimensional tolerance of 0.02mm and flatness within 0.05mm for such parts. In addition, we can also control the surface appearance, color difference, coating adhesion and so on.

● Springs and various wire forming products

We can provide customized services for precision springs and various wire forming products, such as tension springs, torsion springs, compression springs, flat wire springs, spring washers, wave spring pads, spring claps, etc. Our company has passed IATF16949 Certification and can provide customized services for various industries including automobile, medical treatment, communication, electronics, instrumentation, toys, etc. Our spring production is highly automated so the prices are very competitive.

Inquiry